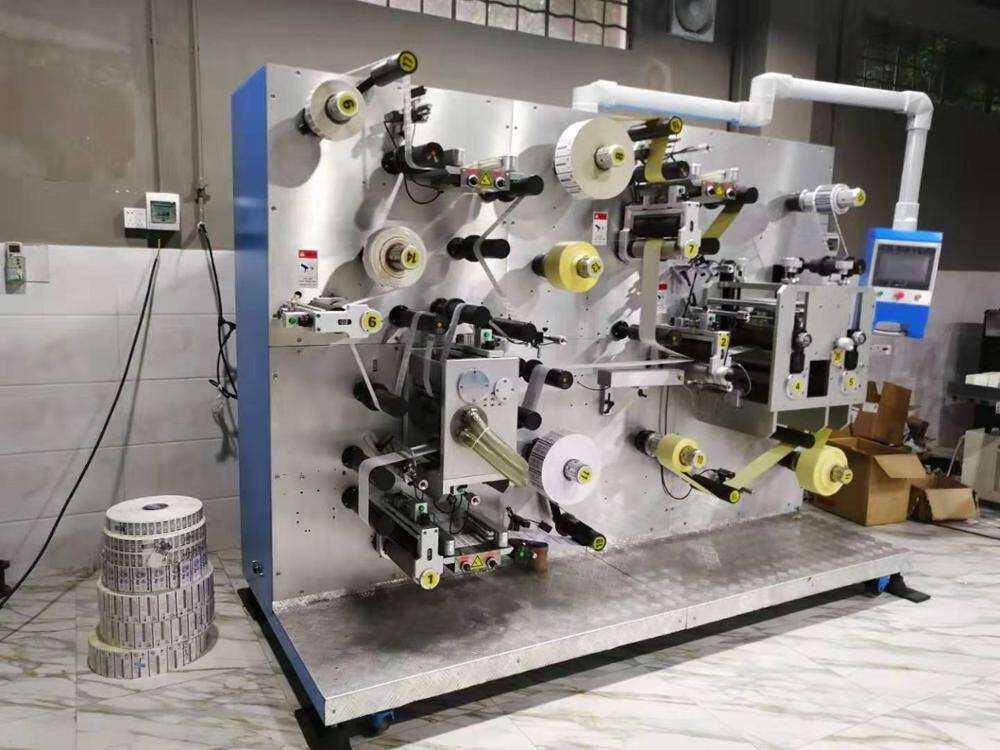

RFID Labeling Machine

This machine is a smart solution for printing and applying RFID labels, which are used for tracking and managing inventory, assets, and security. The machine can encode and verify the RFID tags, as well as print text, graphics, and barcodes on the labels. The machine can handle different types of label materials and sizes, and can be integrated with existing systems. The machine is user-friendly and reliable, and can produce up to 200 labels per minute. The machine is ideal for industries such as retail, manufacturing, healthcare, and supply chain. With this machine, you can optimize your labeling and data collection processes.

- Overview

- Parameter

- Inquiry

- Related Products

The RFID Labeling Machine is a specialized piece of equipment designed to apply Radio-Frequency Identification (RFID) tags onto products or packaging with high accuracy and efficiency. It is widely used in industries such as logistics, retail, and pharmaceuticals, where precise tracking and identification of products are crucial.

This machine is equipped with advanced technology that enables it to apply RFID tags onto labels or directly onto product surfaces. The machine can handle various types of RFID tags, including passive, active, and semi-passive tags, and can apply them onto different materials such as paper, plastic, and metal.

The RFID Labeling Machine utilizes an automatic feeding system that ensures continuous and smooth material feeding. The feeding mechanism aligns the labels or products precisely, ensuring that the RFID tags are applied accurately. This helps to minimize errors and ensure consistent application results.

The control panel of this machine features an intuitive interface that allows operators to easily set and adjust parameters such as labeling speed, label size, and RFID tag placement. Users can easily switch between different product sizes and RFID tag types, enabling quick changeover times and facilitating efficient production.

To further enhance productivity, the RFID Labeling Machine also incorporates advanced features such as automatic label detection and error correction. These features help to eliminate errors and reduce downtime, improving overall efficiency and reducing labor costs.

In addition to its advanced features, the RFID Labeling Machine also incorporates safety mechanisms to prevent accidents and protect operators. Emergency stop buttons, safety sensors, and protective covers ensure a safe work environment during operation.

Overall, the RFID Labeling Machine offers a comprehensive solution for the precise and efficient application of RFID tags. Its advanced technology, automatic feeding system, user-friendly interface, and safety mechanisms contribute to improved productivity, reduced errors, and enhanced product quality. With its versatility and adaptability, this machine is an ideal choice for businesses seeking to optimize their RFID tagging processes.

Applicable Industries |

Garment Shops, Manufacturing Plant, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Food & Beverage Shops, Advertising Company |

Showroom Location |

Viet Nam, Pakistan, India, Mexico, Bangladesh, South Africa |

Place of Origin |

Guangdong, China |

Weight |

3000KG |

Warranty |

1 Year |

Key Selling Points |

Multifunctional |

Machinery Test Report |

Provided |

Video outgoing-inspection |

Provided |

Warranty of core components |

1 Year |

Core Components |

Gear, Motor, Engine, Bearing, Gearbox |

Type |

LABELING MACHINE |

Condition |

New |

Automatic Grade |

Automatic |

Driven Type |

Electric |

Voltage |

380V |

Brand Name |

YOUNGSUN |

Dimension(L*W*H) |

2800X1250X2350MM |

Function |

RFID chips,paper composite |

Feature1 |

It ensures composite RFID chips both sides or one side, |

Feature2 |

Die cut and smart tag production Is available after bonding |

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BN

BN

BS

BS

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ

KY

KY