Smart Label Coding Machines: Enhancing Identification Systems

Understanding Smart Label Coding Machines

Smart label coding machines are a groundbreaking innovation in the labeling industry, designed to enhance identification and tracking of products. These machines primarily serve to encode information onto labels, leveraging technologies like QR codes, RFID, and NFC to facilitate seamless integration with various identification systems. By embedding digital technology into traditional labeling, these machines enable real-time data communication, enriching product data beyond simple identifiers. This integration empowers businesses to undertake more efficient inventory management, product authentication, and consumer engagement by offering interactive information access.

Key Features and Capabilities

Smart label coding machines offer automation features that massively enhance productivity. Automation ensures consistent output quality while reducing manual effort and errors, significantly expediting the labeling process. In addition, these machines boast extraordinary precision and speed capabilities, crucial for maintaining high-quality standards across diverse labeling tasks. Furthermore, their compatibility with multiple materials and label types makes them versatile solutions, accommodating an array of industrial applications. Such capabilities ensure that the machines can efficiently handle different labeling needs, from simple alphanumeric codes to complex RFID installations, across varied environments and use cases.

Applications of Smart Label Coding Machines

In Consumer-Facing Applications

Smart label coding machines are instrumental in consumer-facing applications, particularly in retail. They are used for product labeling and tracking, ensuring that consumers have up-to-date information about products. For example, interactive labels might contain QR codes that, when scanned, offer consumers additional product information or promotional offers, enhancing the overall shopping experience. Furthermore, a number of case studies have shown their effectiveness in consumer engagement, such as allowing customers to interact with brands directly through their smartphone apps, ultimately boosting customer loyalty.

In Business-Facing Applications

In business-facing settings, smart label coding machines serve vital roles in logistics and manufacturing. They significantly improve inventory management and tracking by automating the identification and handling of products throughout the supply chain. Manufacturing firms also benefit from the precise asset tracking these machines provide, leading to improved operational efficiency. The impact on supply chain transparency and efficiency cannot be overstated, as businesses can leverage real-time data to optimize processes and reduce operational costs.

Types of Smart Label Coding Machines

Smart label coding machines are revolutionizing the way data is embedded in products for diverse applications. They come in different types, each designed to meet specific needs across industries.

QR Code Label Machines

QR code label machines work by encoding information in a quick-response format that can be scanned by smartphones and other devices. The primary benefit of using QR codes is the rapid access to information they provide, making them invaluable for applications that require quick data retrieval. Industries such as retail, hospitality, and entertainment have greatly benefited from QR code labeling, utilizing it for inventory management, enhancing customer experiences, and facilitating payments. This technology supports industries in offering seamless interactions between consumers and products.

RFID Tag Machines

RFID tag machines leverage radio frequency identification technology to transform how products are tracked and managed. Unlike traditional barcode systems, RFID allows for real-time tracking and improved security because it does not require a direct line of sight for scanning. This technology is extensively used in logistics and retail, where it aids in inventory management and enhances supply chain transparency. The security and efficiency of RFID tags make them ideal for applications that demand high precision and extensive data management.

NFC Tag Machines

NFC tag machines use Near Field Communication technology to allow seamless interactions between electronic devices and media content. Unlike RFID and QR codes, NFC tags can be password protected, making them more secure. They are often utilized in consumer electronics, payments, and asset management to enhance user interaction and secure data transactions. For example, in consumer electronics, NFC enables easy data exchange, while in the realm of payments, it supports contactless transaction methods. Comparing NFC to its peers, it stands out for its versatility and heightened security features.

Benefits of Using Smart Label Coding Machines

Enhanced Efficiency and Accuracy

Smart label coding machines enhance operational efficiency and accuracy by automating labeling processes, significantly reducing human error. For instance, according to industry reports, companies implementing automated systems have seen processing times improve by approximately 30% due to fewer manual interventions. Furthermore, accuracy in label application has improved markedly, ensuring product information is consistently correct and up-to-date.

Improved Consumer Engagement

Smart labels play a pivotal role in improving consumer engagement by offering interactive features that enhance the user experience. For example, companies using interactive labels have observed a marked increase in customer interaction rates, as detailed in several case studies. These labels provide detailed product information, allowing consumers to make more informed purchasing decisions and fostering a deeper connection with the brand.

Cost-Effective Solutions

Investing in smart label machines can lead to substantial cost savings by minimizing labor costs and reducing labeling errors. Over the long term, these machines offer financial benefits that outweigh their initial investment cost, proving more economical compared to traditional labeling methods. When analyzing cost, businesses find that the return on investment in smart labeling technology quickly surpasses that of conventional methods, offering a compelling economic advantage.

Product Overview

On Running Registration Flexo Narrow Garment Label Printing Machine

The On Running Registration Flexo Narrow Garment Label Printing Machine is optimized for producing high-quality garment labels. Leveraging advanced flexo printing technology, it achieves precise pattern alignment, ensuring consistency across narrow-width label prints. This machine's high precision and efficiency make it an ideal addition for businesses in the garment industry, offering operational advantages through its accurate running registration function.

Simple Operation Fast Speed Automatic Ultrasonic Cutting Machine

This machine exemplifies precision with its ultrasonic cutting technology, achieving fast speeds and simplicity of operation. It's engineered for versatility, handling various materials like cloth and plastics with ease. The machine's straightforward operation and rapid processing make it essential for industries requiring precise and efficient cutting solutions.

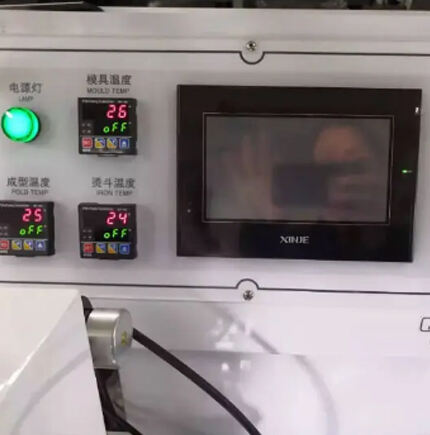

SW330 Automatically Special Ultrasonic Center Cut and Fold Machine with PLC Control Systom

The SW330 machine boasts a sophisticated PLC control system, enhancing precision in center cutting and folding operations. Its ultrasonic technology ensures high efficiency, automatically handling complex tasks with ease. Such automation streamlines processes, proving invaluable for enterprises aiming to optimize cutting and folding tasks.

Taiho Brand Automatic Roll To Roll Screen Printing Machine

Taiho Brand's Roll To Roll Screen Printing Machine utilizes an advanced screen printing process for high-volume applications. Known for its efficiency and reliability, it supports multi-color printing and robust material handling. This machine is essential for large-scale production needs in industries that demand durability and high-quality outputs.

Book Cover Cut Fold Machine

The Book Cover Cut Fold Machine is specialized for book cover production, offering seamless automation in cutting and folding tasks. Its precision is enhanced through an advanced control system, catering to diverse book dimensions and materials. The machine's efficiency suits the demands of the publishing and printing industries, optimizing production with minimal operational input.

Frequently Asked Questions

What are smart label coding machines used for?

Smart label coding machines are used to encode information onto labels using technologies like QR codes, RFID, and NFC to enhance product identification and tracking.

How do these machines improve business operations?

They improve business operations by automating labeling processes, enhancing inventory management, product tracking, and supply chain transparency, thereby reducing operational costs.

What are the advantages of using QR codes, RFID, and NFC technologies?

QR codes offer quick information access, RFID provides real-time tracking without line-of-sight scanning, and NFC supports secure, password-protected interactions between electronic devices.

Recommended Products

Hot News

-

Reflect On The Cultural Significance Of The Printing Press In Preserving And Disseminating Knowledge

2023-12-08

-

The Role Of The Printing Press In The Global Economy

2023-12-08

-

Environmental Impact: Analyzing The Environmental Footprint Of The Printing Industry

2023-12-08

-

The Frontier Of Printing: 3d Printing And Its Industrial Renaissance

2023-12-08

-

The Evolution And Impact Of The Printing Press

2023-12-08

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BN

BN

BS

BS

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ

KY

KY